Plate mounting in flexographic printing is the system of appropriately attaching the flexo printing plate to the printing cylinder. This step is crucial for preserving registration accuracy, consistent stress, and superior ink transfer. Proper mounting guarantees particular alignment, which is essential for first-rate prints and minimizes defects including misregistration and dot benefit.

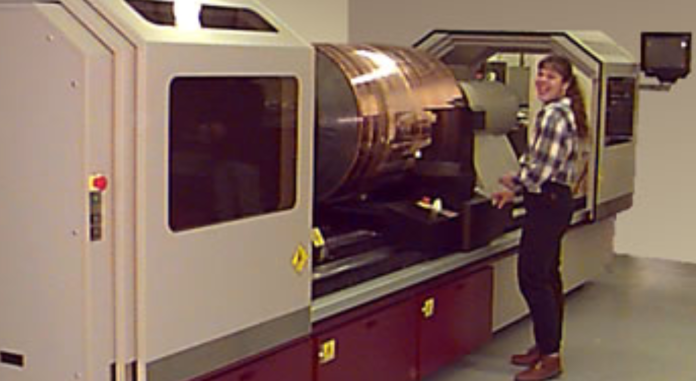

Techniques consist of the use of sticky-back tapes, magnetic cylinders, or mechanical clamps. Advanced systems regularly appoint digital alignment equipment and automated functions to decorate efficiency, lessen setup time, and make the lifestyles of plates and cylinders, contributing to standard print first-rate and operational effectiveness.

Effect of Plate Mounting on Flexographic Printing

Plate mounting is a crucial issue of the flexographic printing method, once impacting print fine, registration accuracy, and average operational performance. Here’s an in-intensity exploration of the way plate mounting influences flexographic printing:

Registration Accuracy

Right plate mounting ensures that the printing plate is appropriately aligned on the cylinder. This precision is vital for keeping registration accuracy, that’s the perfect alignment of different hues or images at the substrate. Misregistration can result in color overlaps, gaps, and poor print high-quality. Superior plate mounting structures use virtual cameras, sensors, and automated controls to align plates as they should be.

Print Quality

The mounting technique impacts the pressure with which the plate contacts the substrate. Choppy mounting can cause inconsistent stress, ensuing in versions in ink transfer. This can cause troubles together with dot benefit, where ink spreads past the supposed place, or insufficient ink switch, main to dwindled or incomplete prints. Excellent mounting minimizes the possibilities of air bubbles, wrinkles, or plate lifting, all of which could degrade print quality.

Operational Efficiency

Efficient plate mounting reduces the time required to set up the printing press. Short and precise mounting strategies can significantly decrease setup instances, increasing the overall productivity of the printing operation. Modern plate mounting system regularly includes automatic capabilities that beautify performance. Proper mounting techniques lessen the probability of plate-related troubles all through printing, minimizing press downtime and protection needs.

Plate and Cylinder Wear

Correct plate mounting minimizes pressure and both the printing plate and the cylinder. Misalignment or mistaken tension can cause immoderate put on, shortening the lifespan of the plates and cylinders. Ordinary inspection and preservation of the mounting system make certain that plates are mounted efficaciously each time, similarly decreasing wear and related fees.

Ink Switch Performance

Right plate mounting ensures that the plate makes constant contact with the substrate, optimizing ink transfer. This is vital for accomplishing the preferred shade density and insurance, particularly in high-velocity printing environments. Inadequate mounting can lead to defects consisting of ghosting (unwanted photo replication), haloing (a faint definition around the print), and streaking. Those defects can be minimized employing ensuring the plate is mounted successfully, with even strain and no distortions.

Coping with Complex Designs

For complicated designs and high-quality info, accurate plate mounting is critical. Even minor misalignments can distort tricky patterns and small textual content, leading to poor duplicate first-rate. In high-resolution printing, where precision is paramount, the high quality of plate mounting immediately influences the capability to reproduce the best strains, halftones, and gradients appropriately.

Mounting Strategies

Sticky back tapes, which can be adhesive-sponsored foam tapes, are commonly used in plate mounting. These tapes offer a cushioning effect that facilitates keep consistent strain and accommodate mild versions in substrate thickness. A few mounting structures use mechanical clamps or pins to secure the plate. Those systems can provide strong and strong mounting however might also require more manual adjustment and can be much less bendy than sticky back or magnetic systems.

Summary

Plate mounting is a pivotal aspect in flexographic printing, influencing each factor from print satisfaction and registration accuracy to operational performance and equipment durability. Right mounting ensures consistent stress, correct alignment, and gold-standard ink transfer, all of which can be vital for producing superb prints. With the aid of minimizing setup times, lowering wear, and enhancing consistency, effective plate mounting plays an important function in the success of flexographic printing operations.