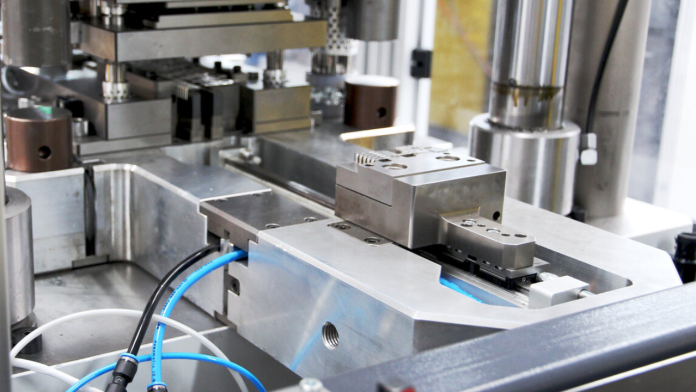

A plastic injection molding machine melts plastic and injects it into molds to create unique, repeatable components for numerous programs. The interaction includes a few key stages: softening the plastic, infusing it into the form under high pressure, cooling it to set, and afterward firing the completed part. These machines comprise of a container, an infusion unit, and a clasping unit.

The container takes care of crude plastic pellets into the infusion unit, where they are warmed and softened. The liquid plastic is then constrained into the form hole, which is held firmly by the clasping unit to forestall spills and guarantee accuracy standard injection molding machine is generally utilized because of its effectiveness, repeatability, and capacity to deliver complex shapes with fine subtleties. This innovation is fundamental in enterprises like automotive, electronics, medical devices, and purchaser products.

Environmental Considerations in Plastic Injection Molding Machines

Plastic injection molding machines are pivotal in producing an extensive variety of plastic products, however, they also pose sizeable environmentally demanding situations. Addressing those considerations is crucial for reducing the ecological footprint of producing strategies. Right here are a few key environmental considerations associated with plastic injection molding machines

Energy Consumption

Power consumption is one of the main environmental problems associated with plastic injection molding equipment. For such machines to soften plastic resin, inject it into molds, and chill the finished goods, a significant quantity of power is needed. In addition to increasing greenhouse gas emissions, excessive power use raises production costs.

To cope with this problem, manufacturers are increasingly more adopting energy-green technologies in injection molding machines. These consist of variable frequency drives (VFDs), which regulate motor pace primarily based on demand, lowering electricity wastage at some point of idle durations. Additionally, enforcing insulation substances and optimizing heating and cooling approaches can, in addition, enhance energy performance.

Material Waste and Recycling

Plastic injection molding generates waste at numerous levels of the manufacturing system. This waste consists of extra plastic material from sprues, runners, and faulty elements, which frequently emerge in landfills or incinerators, posing environmental hazards. Moreover, using virgin plastic resin exacerbates useful resource depletion and pollution associated with extraction and manufacturing.

To mitigate those environmental influences, manufacturers are increasingly specializing in waste reduction and recycling. Technologies including hot runner systems decrease material waste with the aid of reusing excess plastic in the injection molding method. Furthermore, integrating recycled plastic resin (regrind) into manufacturing reduces reliance on virgin materials and lessens the environmental footprint of plastic products.

Emissions and Air Quality

Plastic injection molding machines emit pollution and greenhouse gases during operation, by and large from heating and melting plastic resins. Those emissions contribute to air pollution and climate alternations, posing health risks to both people and surrounding communities. Moreover, volatile organic compounds (VOCs) released from plastic substances can degrade indoor air quality in manufacturing centers.

To address emissions and air pleasant issues, producers can put into effect diverse techniques. Putting inefficient exhaust systems with filters allows seize and deal with pollution earlier than they are released into the atmosphere. Furthermore, substituting conventional plastic resins with low-VOC or bio-based total options reduces emissions in the course of manufacturing and improves indoor air quality.

Water Usage and Pollution

At the same time, plastic injection molding isn’t inherently water-in-depth as compared to industries. Like agriculture or textiles, water is still used for cooling molds and equipment. However, improper water control can cause pollutants through the release of infected wastewater into water our bodies. Additionally, imposing wastewater remedy technologies allows the elimination of pollutants and ensures compliance with environmental policies. Furthermore, selecting eco-friendly mold release agents and cleansing solvents similarly reduces water pollutant risks.

Conclusion

Addressing environmental considerations in plastic injection molding machines requires a multifaceted method encompassing electricity efficiency, waste reduction, emissions manipulation, water management, and eco-design. By implementing innovative technology, adopting sustainable practices, and embracing a lifecycle perspective, manufacturers can limit the environmental footprint of plastic injection molding operations while meeting manufacturing needs and regulatory requirements.